Monitoring pipes or a containment application could be time consuming depending on your everyday tasks and duties. Not only could this be a hassle, but determining the characteristics of a leak signal may be challenging if one doesn't have the experience and knowledge. Worst of all, organizing logistics to pinpoint a potential leak when one is not certain may lead to doubts and financial loss in a company.

Let us take the headache away and help you monitor your application. No need to purchase a resistivity meter that may be costly or even flood your quarterly budget tank. We will provide all necessary instruments and equipment to fully execute the survey taking the burden away from your daily tasks.

APPLICABLE ASTM STANDARDS

- ASTM D6747-15 - Selection of Techniques for Electrical Leak Location of Leaks in Geomembranes

LEAK DETECTION MONITORING SOFTWARE

PMAT17

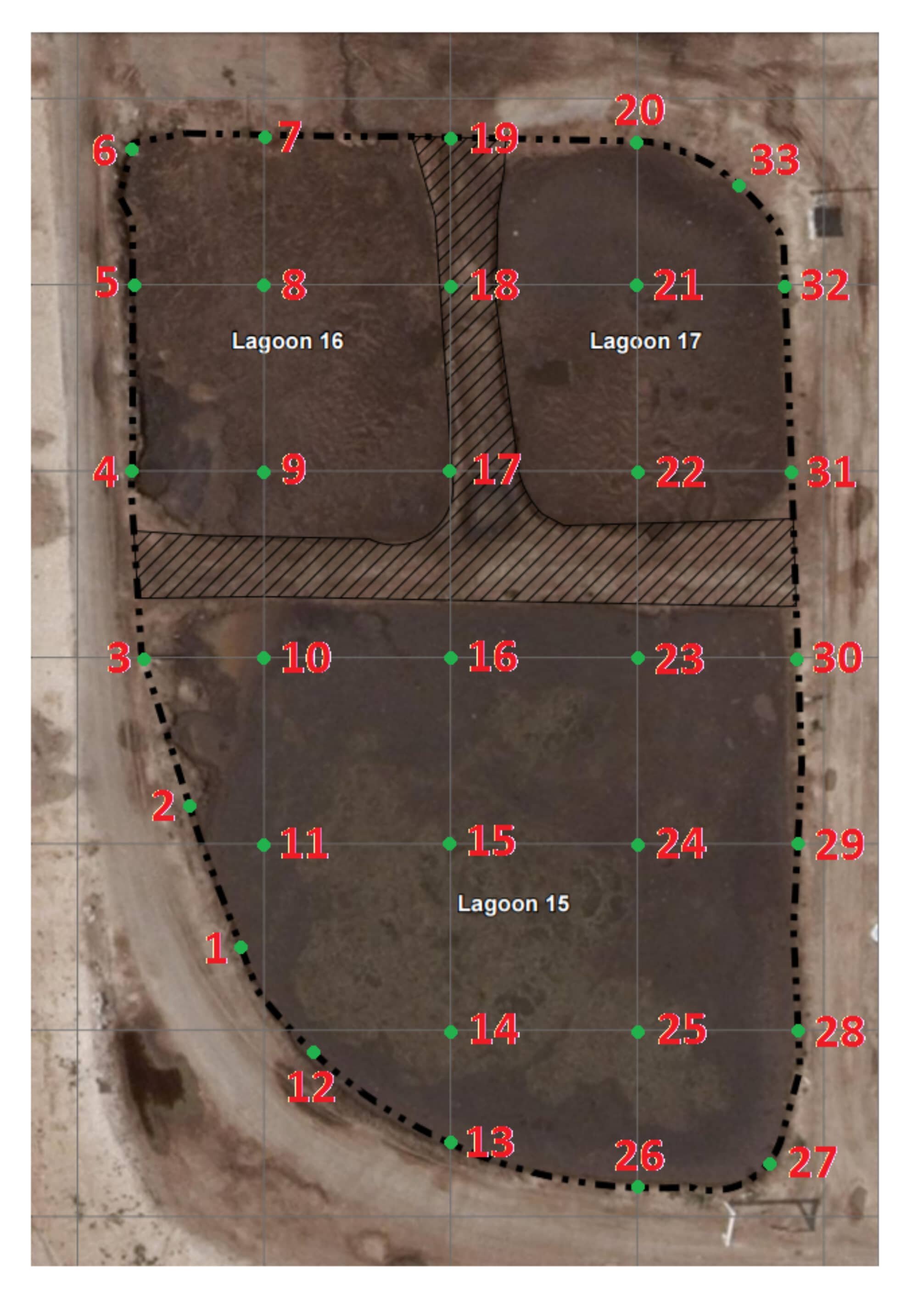

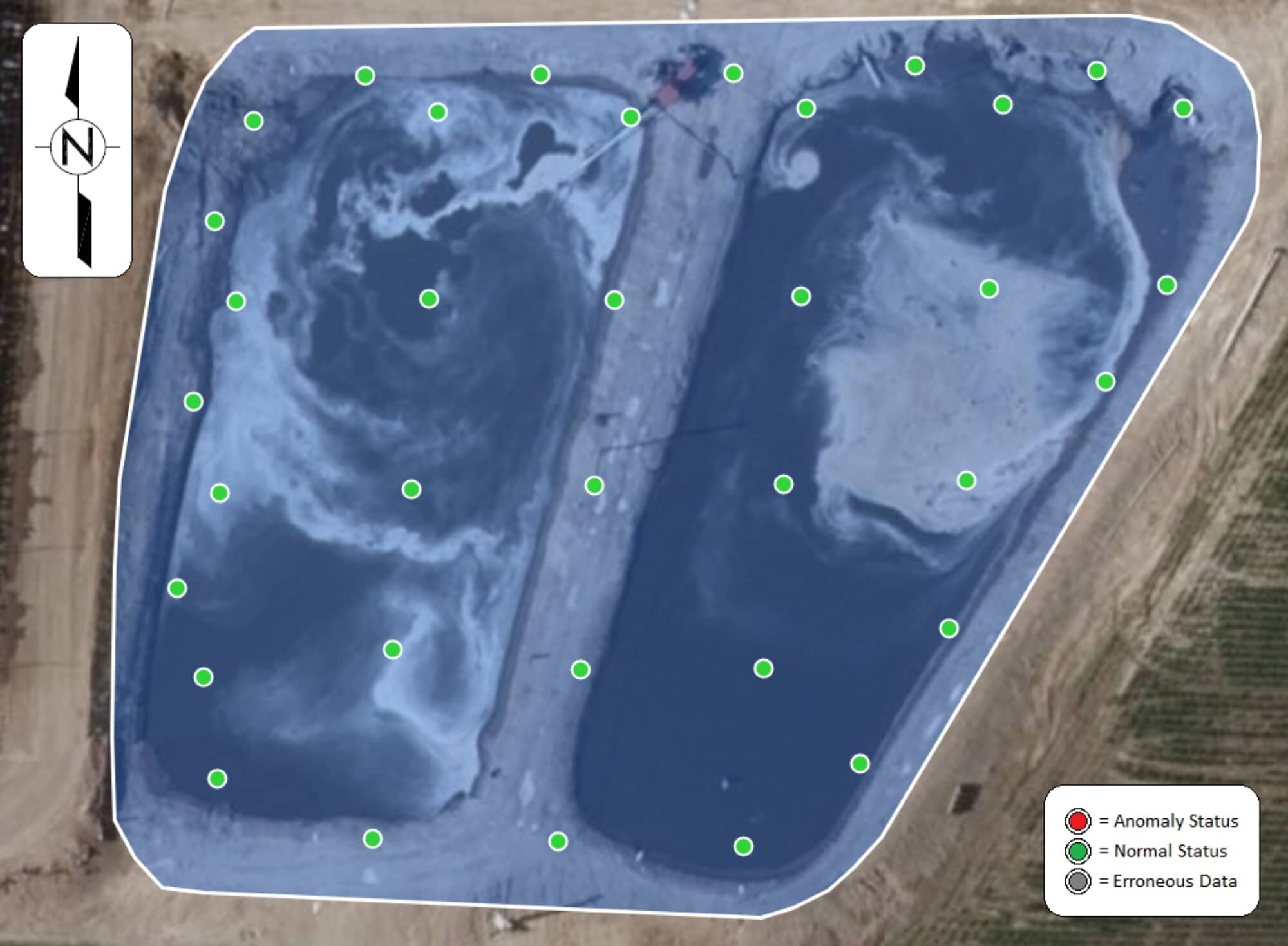

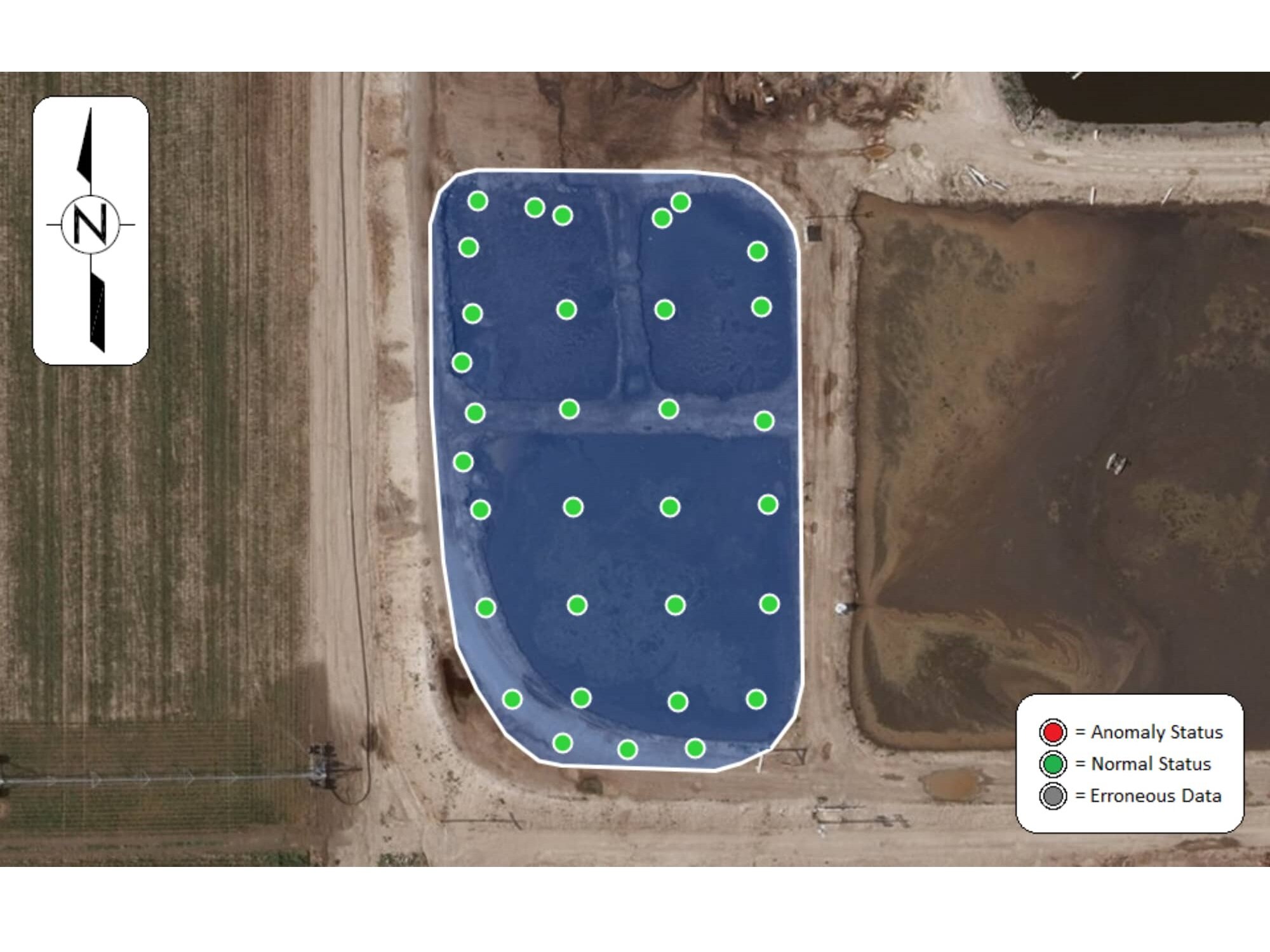

The mostly used monitoring software for the PELM® System is the Potential Measurement Analysis Tool version 17 (PMAT17). This web-based software provides an all-terrain map out of the application, measured resistances with colored indicators, and GPS coordinates at each electrode. Clients are able to access their applications by logging in and analyzing data at their convenience.

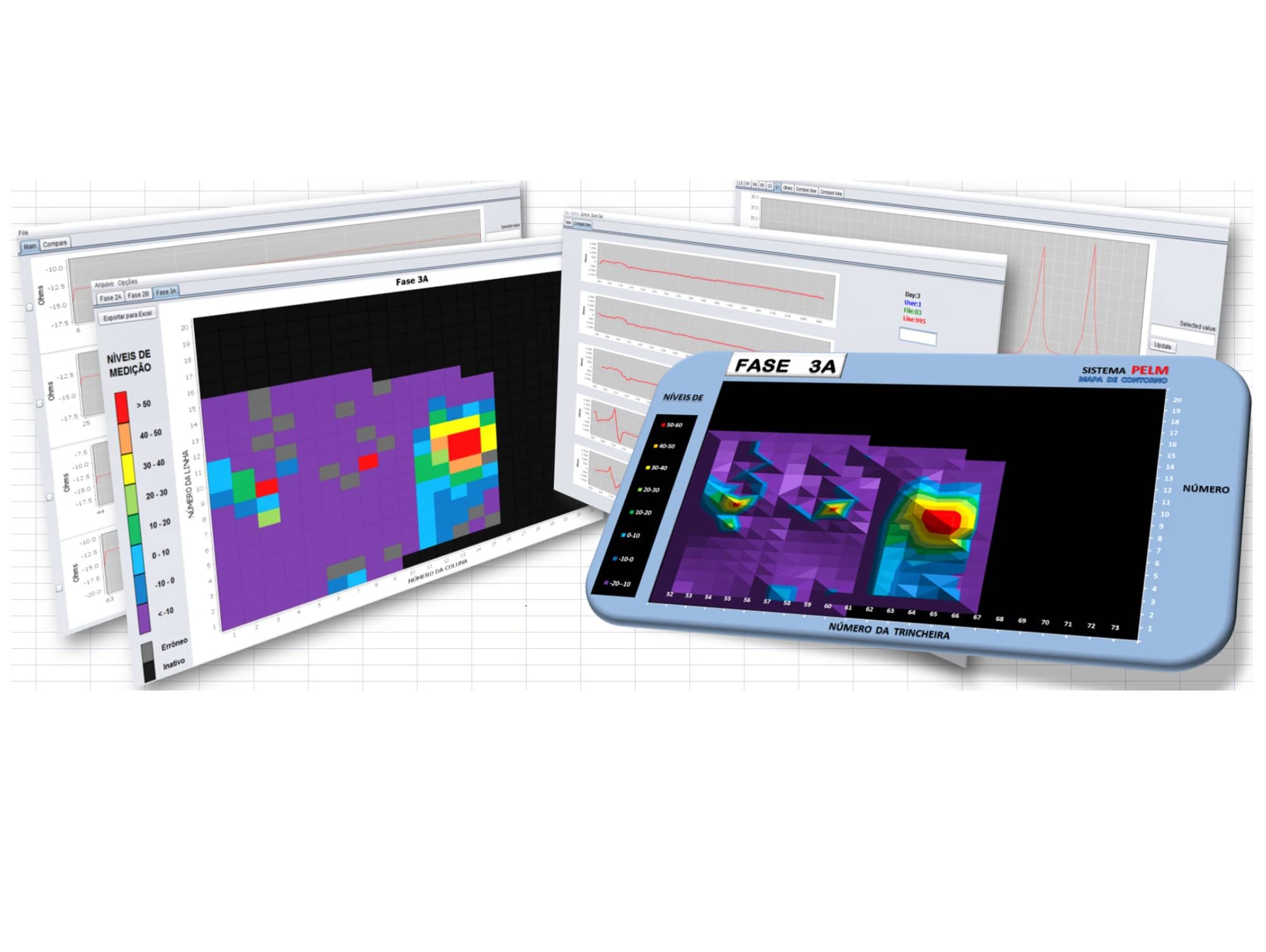

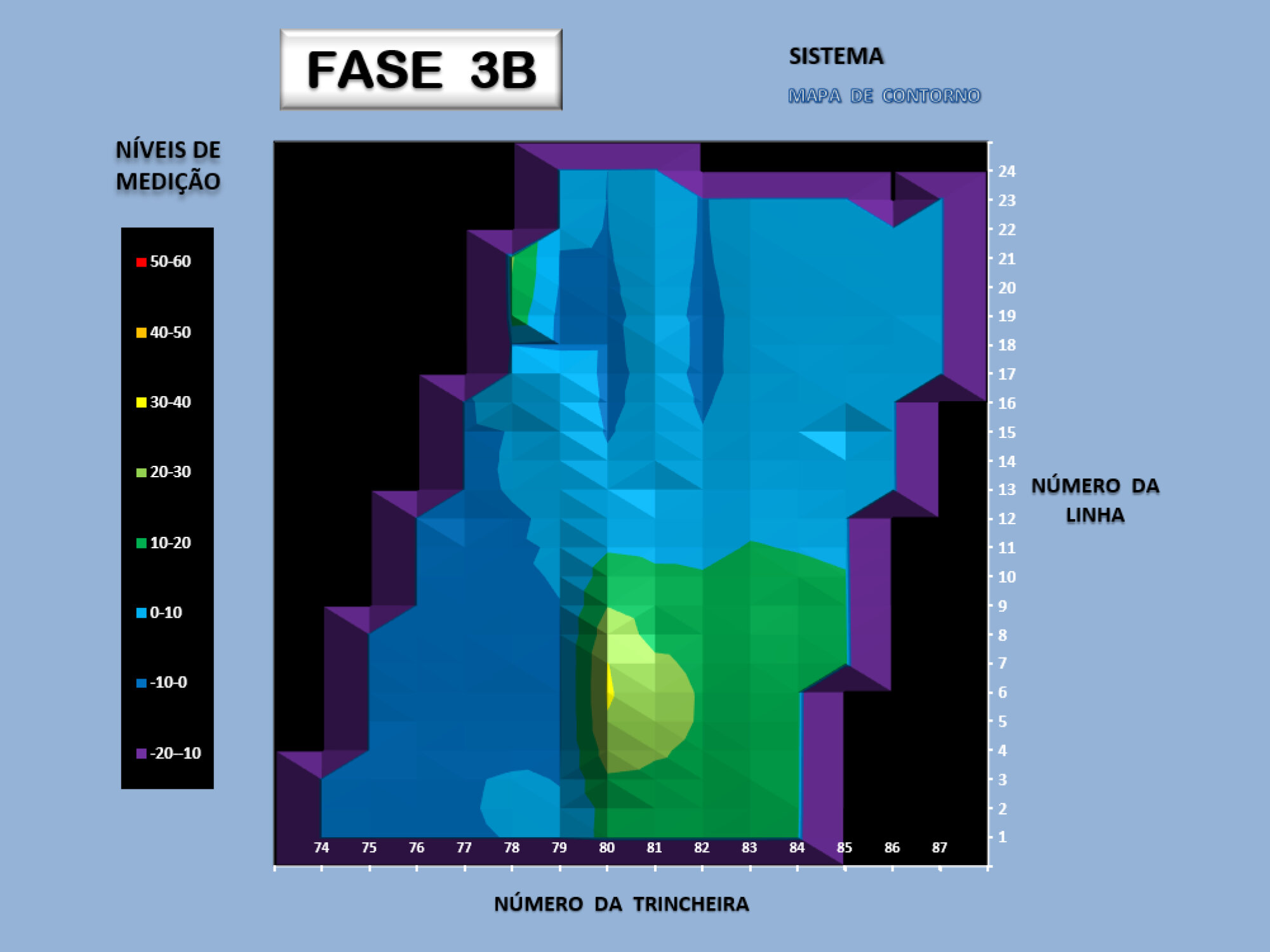

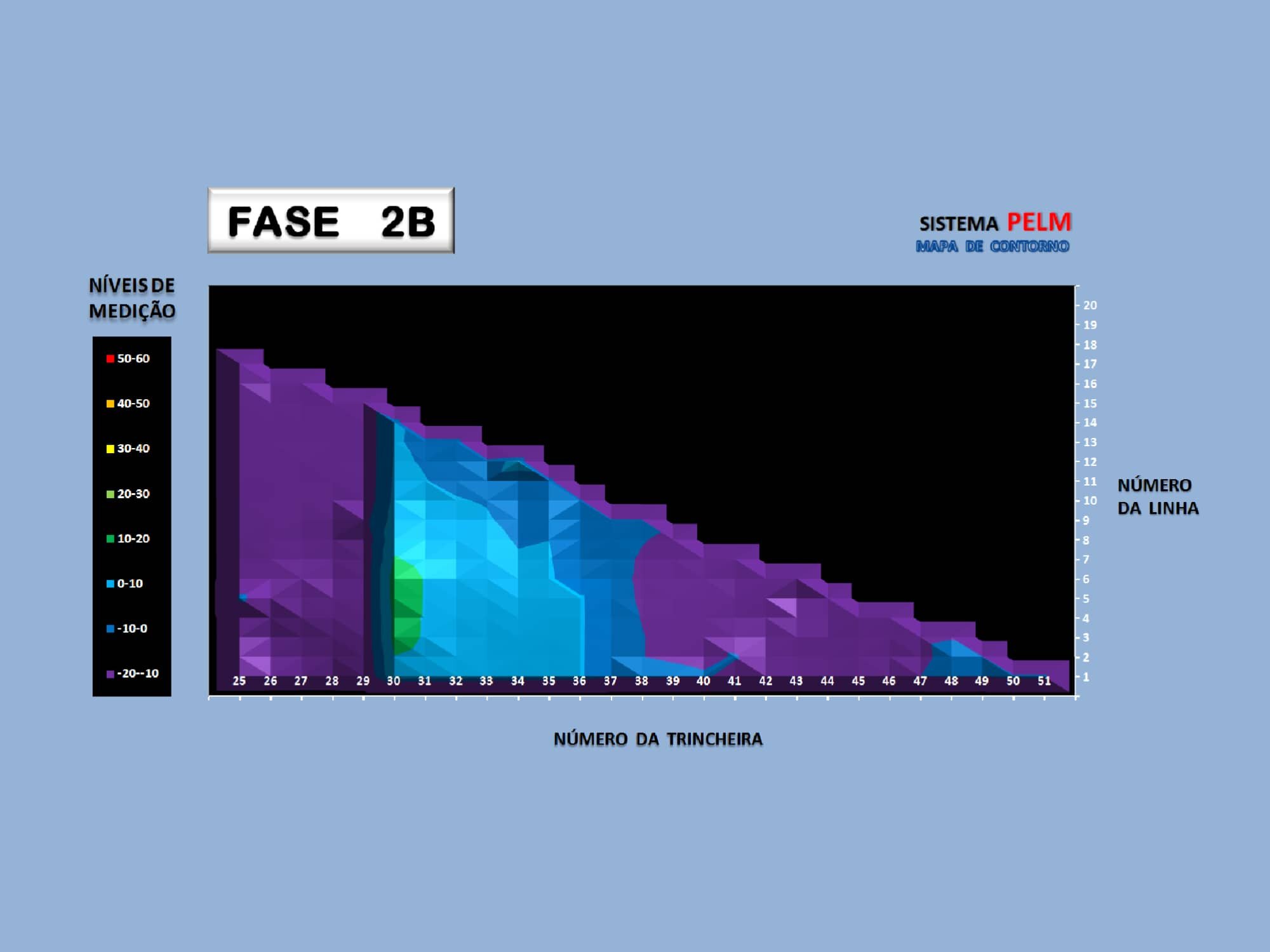

DataPLOT3DC

DataPLOT3DC provides results in a pixelated contour map of the application and enables the user to view and analyze the data with a full spectrum of colors in a selected measurement range. This locally installed software is perfect for displaying an XY coordinate system for applications that are shaped in a simple, geometric configuration.

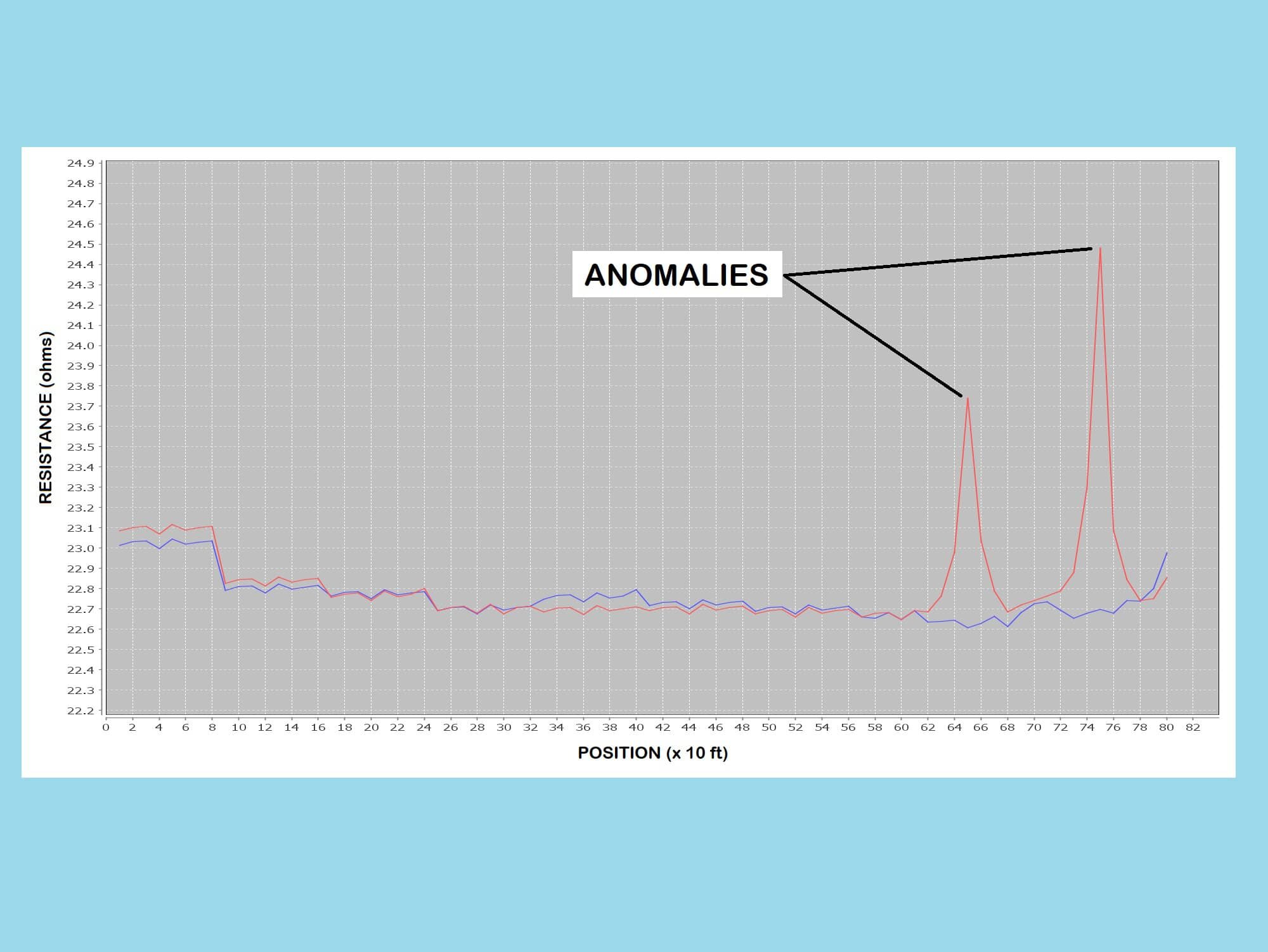

DataPLOT2DL

DataPLOT2DL provides easy-to-read linear graphs that finely details exact resistivity measurements and locations. Clients can opt to select multiple graphs all at once for comparison or even individually for analysis. Because of it’s simplicity, this locally-installed software is best in visually interpreting the characteristics of a leak signal.

Electrical Resistivity

for

Water Containment Systems

Service ID

PELMS - WATR

COVERAGE

DESCRIPTION

REQUIREMENTS

DOWNLOADS

Entire top-most or relative geomembrane-lined containment system covered with liquid

The PELM® Survey of a water containment system can be performed at the frequency of the Client based on regulations and requirements, or during any time a suspect leak may have occurred. This process is conducted by collecting measurement potentials from buried electrodes and analyzed on the leak detection monitoring software. Either PMAT17 or DataPlot3DC will be the applicable software in providing the Client with information regarding the electrode status and general locations of anomalies, if any. Further investigation using a probe will be required to pinpoint the exact location of the suspect anomaly.

liquid depth of 6 in (16 cm)

Currently not available

Electrical Resistivity

for

Soil Containment Systems

Service ID

PELMS - SOIL

COVERAGE

DESCRIPTION

REQUIREMENTS

DOWNLOADS

Entire top-most or relative geomembrane-lined containment system covered with earthen materials

The PELM® Survey of a soil containment system can be performed at the frequency of the Client based on regulations and requirements, or during any time a suspect leak may have occurred. This process is conducted by collecting measurement potentials from buried electrodes and analyzed on the leak detection monitoring software. Either PMAT17 or DataPlot3DC will be the applicable software in providing the Client with information regarding the electrode status and general locations of anomalies, if any. Further investigation using a probe will be required to pinpoint the exact location of the suspect anomaly.

soil depth of 6 in (16 cm)

Currently not available

Electrical Resistivity

for

Nonconductive Buried Pipes

Service ID

PELMS - PIPE

COVERAGE

DESCRIPTION

REQUIREMENTS

DOWNLOADS

Entire length of nonconductive buried pipes

The PELM® Survey for nonconductive buried pipes is performed either after an installation of the PELM® System has been completed, at the frequency of the Client based on regulations and requirements, or during any time a suspect leak may have occurred. This process is conducted by collecting measurement potentials from buried electrodes and analyzed on the leak detection monitoring software. DataPLOT2DL is the primary leak detection monitoring software that will be applicable for buried pipes. The software will provide information regarding the electrode resistive status and general locations of anomalies, if any. Further investigation using a probe will be required to pinpoint the exact location of any suspect anomalies.

soil depth of 3 in (8 cm)

Currently not available

* PELM® is a registered trademark of Beyond Leak Detection